Introduction

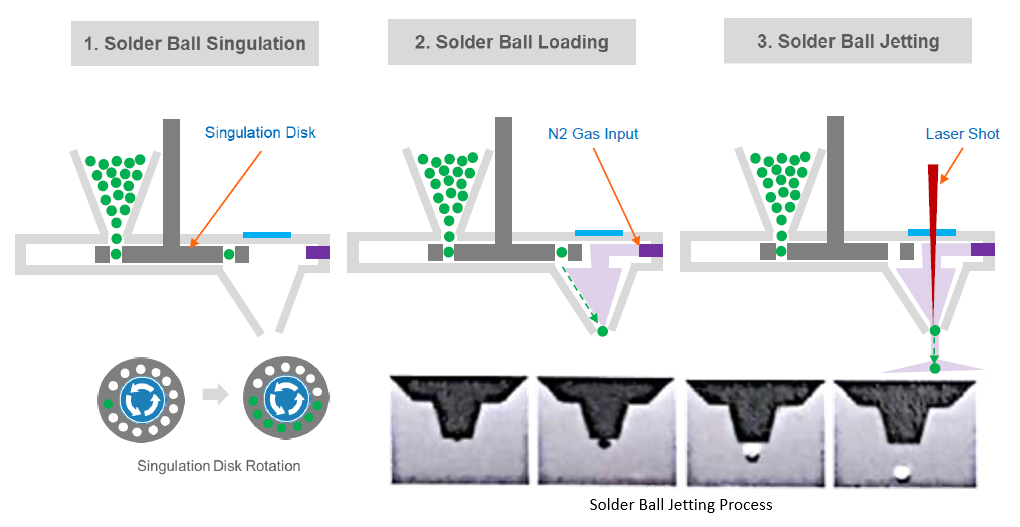

The Laser Solder Ball Jet System is a precise machine made by Korean company DAWON NEXVIEW. First it separate single solder ball. Then it accurately spray molten tin droplets at a certain temperature to the metalized pads by the combined action of laser and nitrogen. Finally, the heat carried by the solder ball droplets will heat the pads to form bumps or to achieve bonding.

The technique is a type of ball grid array(BGA), and it has the advantages of high density, good heat conduction and low-inductance leads.

Specification

The technique is a type of ball grid array(BGA), and it has the advantages of high density, good heat conduction and low-inductance leads.

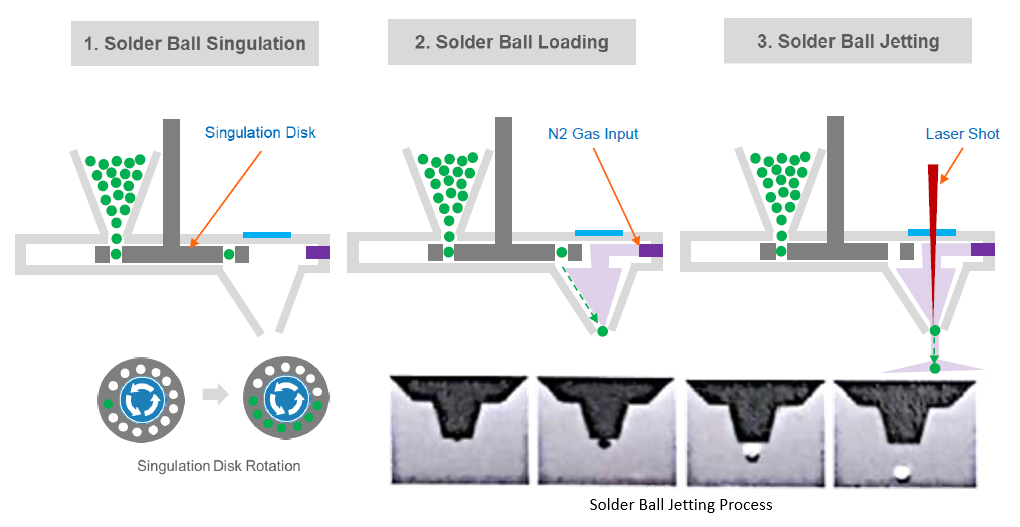

Process

First, separating and loading the solder ball and then jetting the melted solder ball instantly by high power laser and N2 gas pressure.

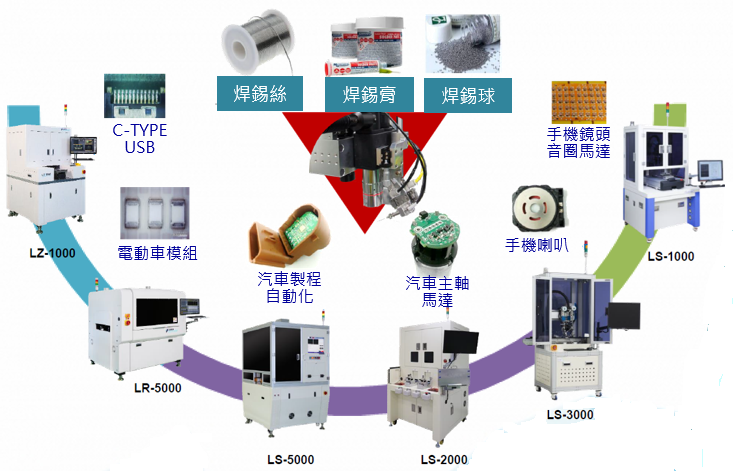

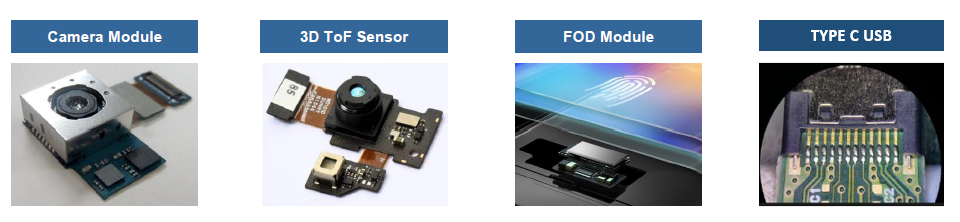

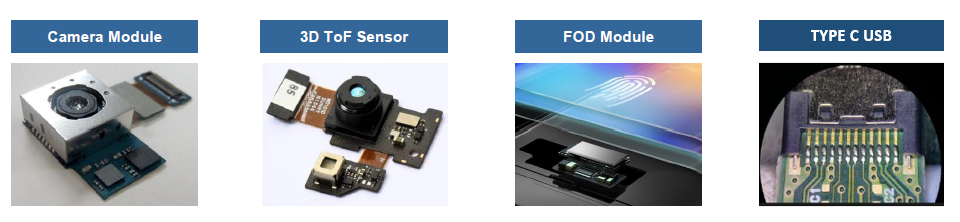

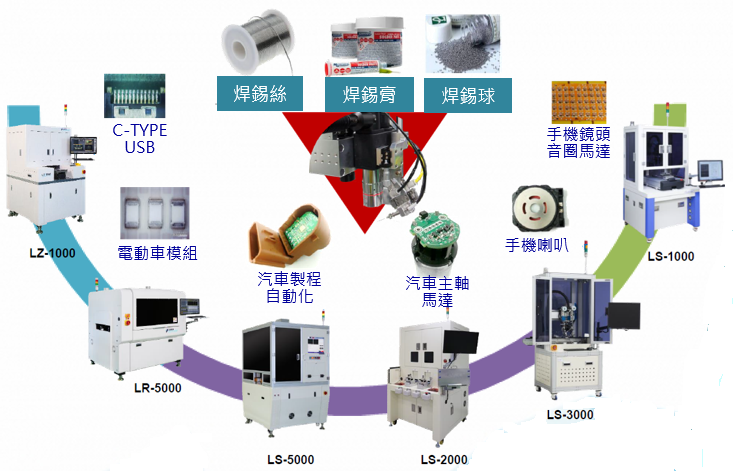

Applications

For electric connection of micro scale and fine pitch component such as Camera Module, VCM, 3D ToF Module, Type C USB and FOD.

Comprehensive Solution

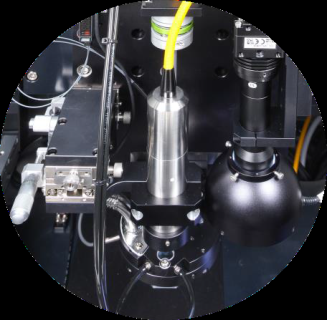

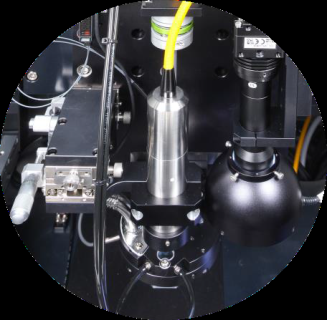

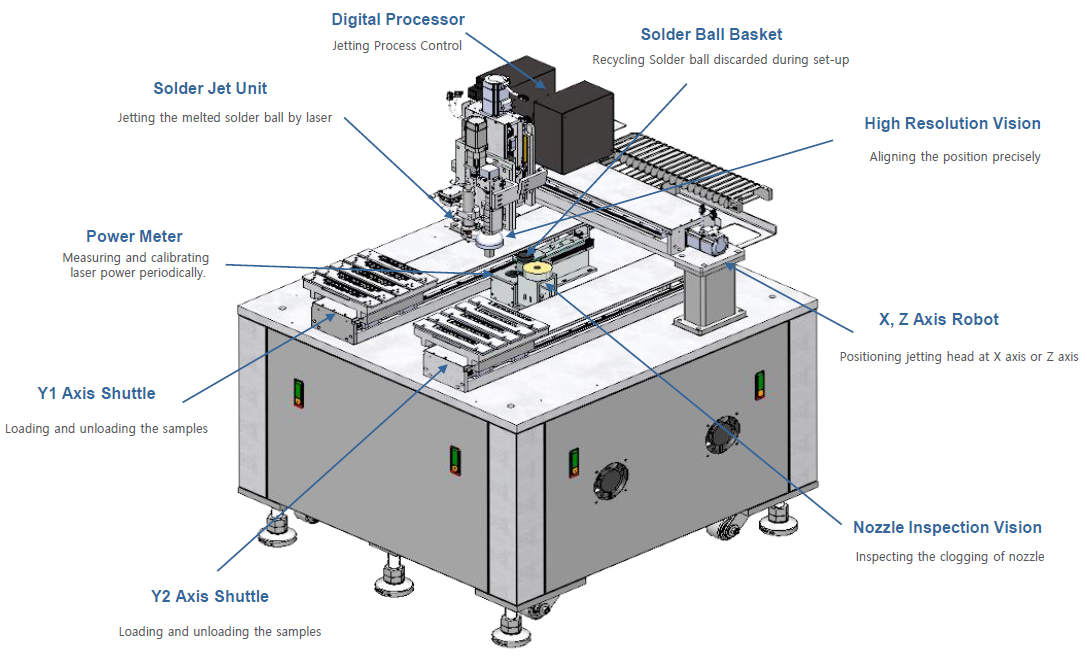

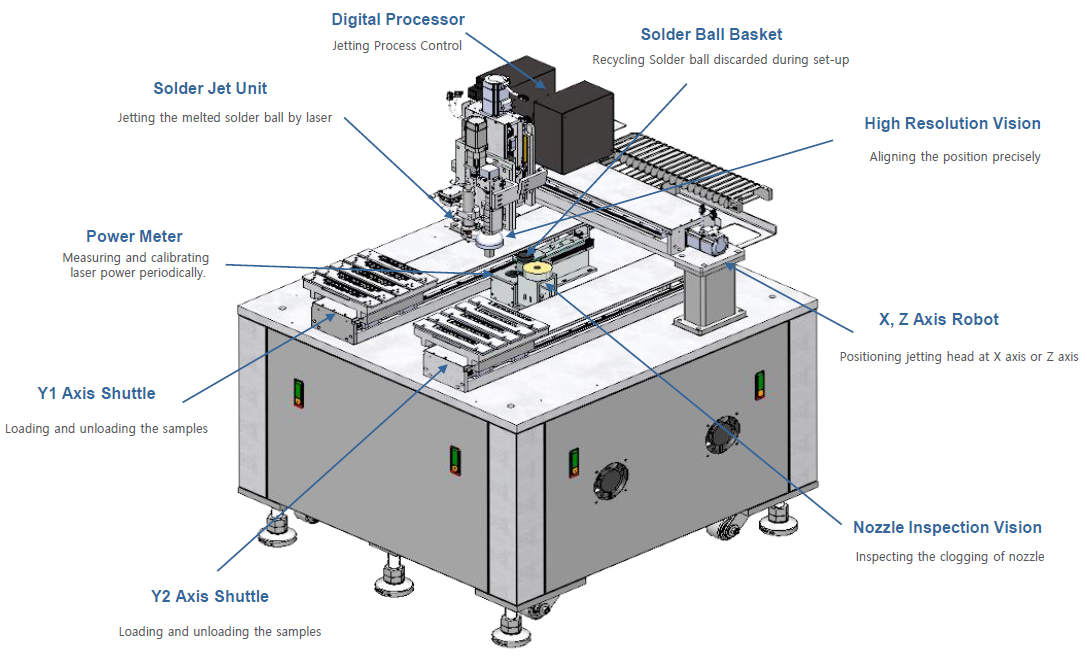

Structural Drawing

Specification

| Speed | Max. 6 Balls/sec |

| Wavelength | 1,070nm |

| Power | 100W~200W |

| Mode | CW, Pulse, ADJ Mode |

| Ball Size | 50um~750um |

| Laser Life Time | 100,000 hours |

| Repeatability | ±5um |

| Work Area | 320mm*320mm |

| Warranty | 2 years |

| Voltage | 220VAC |

Machine Real Shot