Overview

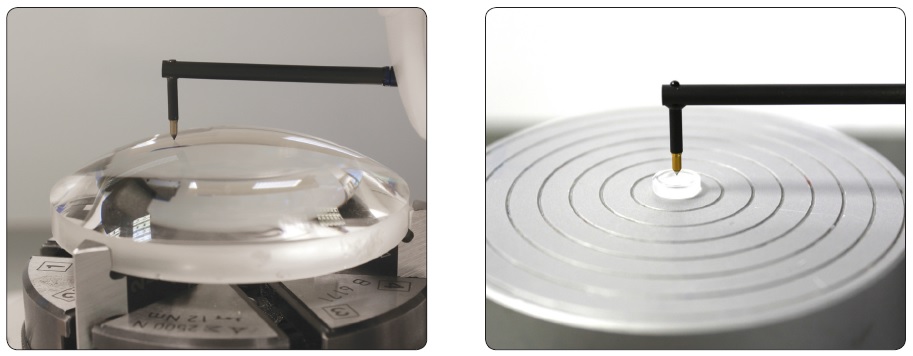

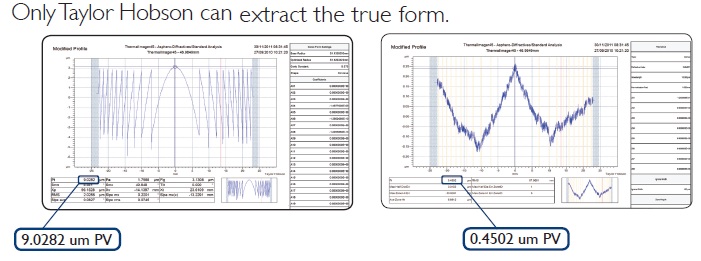

The industry standard for precision optics metrologySimply the best form accuracy when measuring aspheric and diffractive optics

Since its first release in 1984, the Form Talysurf quickly became the number one tool for optics manufactures in measuring aspheric form error. Since then, we have installed thousands across the globe becoming a true industry standard.

The benefits of Talysurf PGI Optics

- New gage design with improved measurement range!

- Advanced Software saves production time and increases output.

New features such as automatic spike removal, P-V/ RMS radius optimization, flanking and sag calculators enable you to reduce subjective measurement analysis errors in a production environment.

- Easy-to-use interface increases productivity.

With automation further reducing operator dependency.

A dedicated user-friendly interface is supplied for the specific measurement of optical moulds and lenses. This interface provides an easy method of instrument operation, presenting clear control options to the operator – ideal for production use.

New vacuum system makes smaller parts easier to hold and reduces errors from part movement.

A dedicated user-friendly interface is supplied for the specific measurement of optical moulds and lenses. This interface provides an easy method of instrument operation, presenting clear control options to the operator – ideal for production use.

New vacuum system makes smaller parts easier to hold and reduces errors from part movement.

(Plastic lenses, small components, large diameter optics, IR glass..etc)

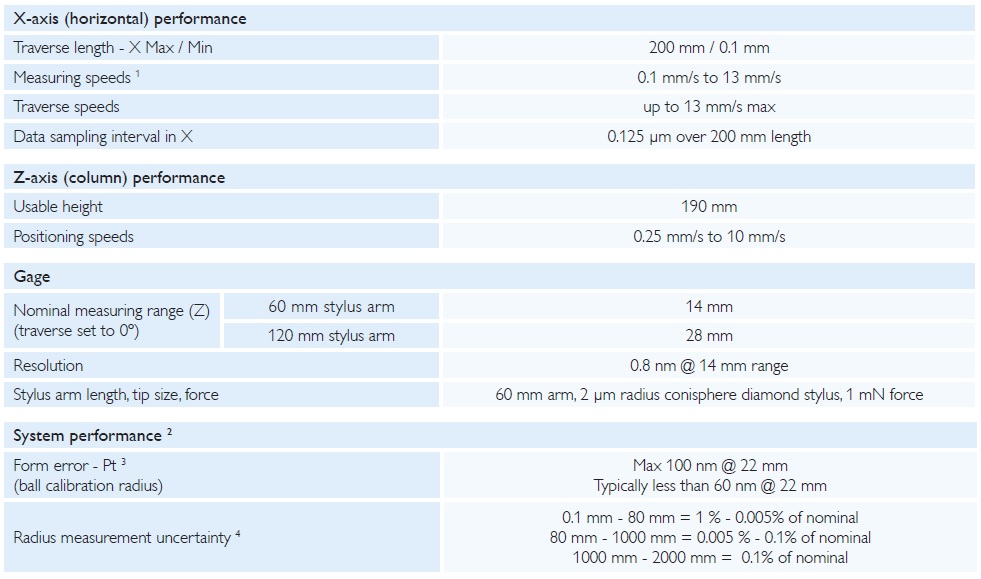

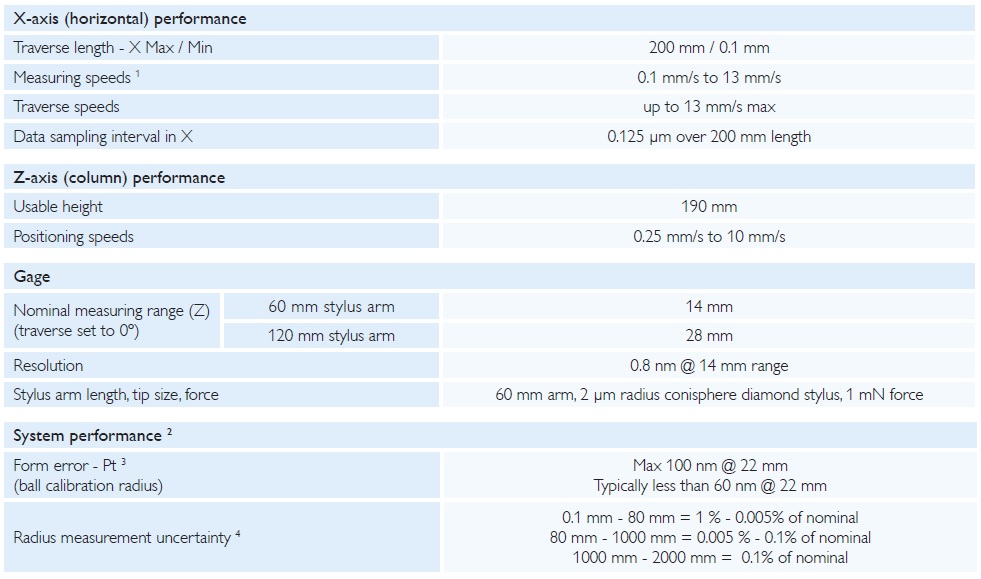

Specification

Applications

The most versatile metrology in the industry

(Plastic lenses, small components, large diameter optics, IR glass..etc)

(Plastic lenses, small components, large diameter optics, IR glass..etc)