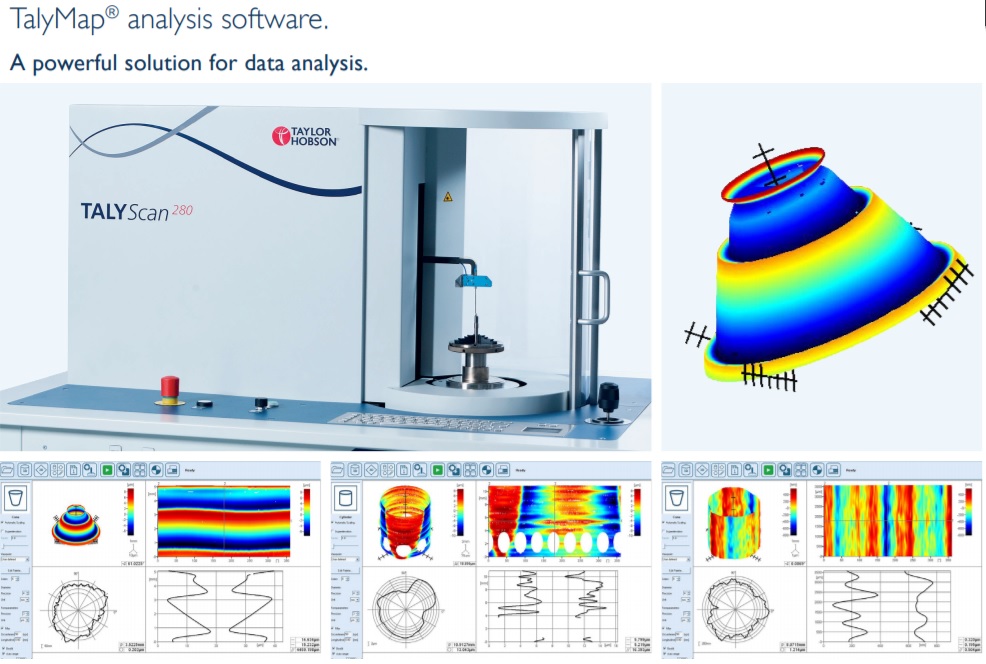

Overview

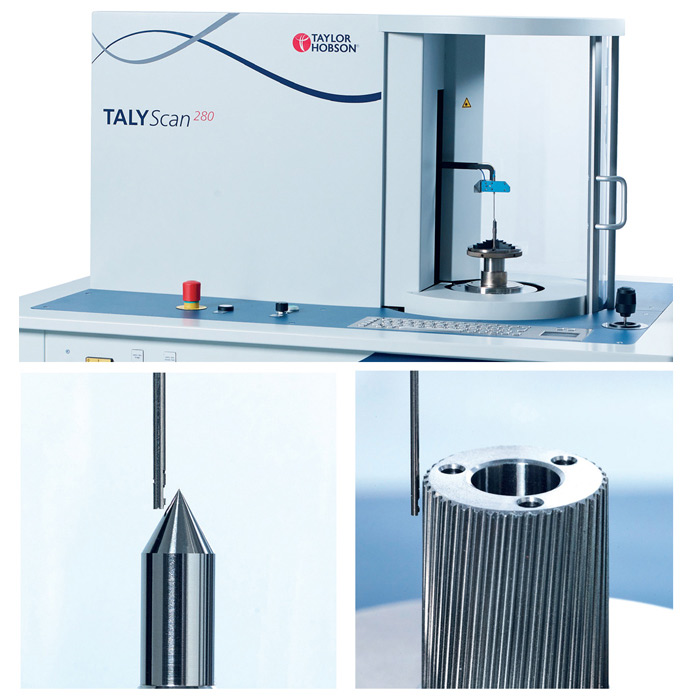

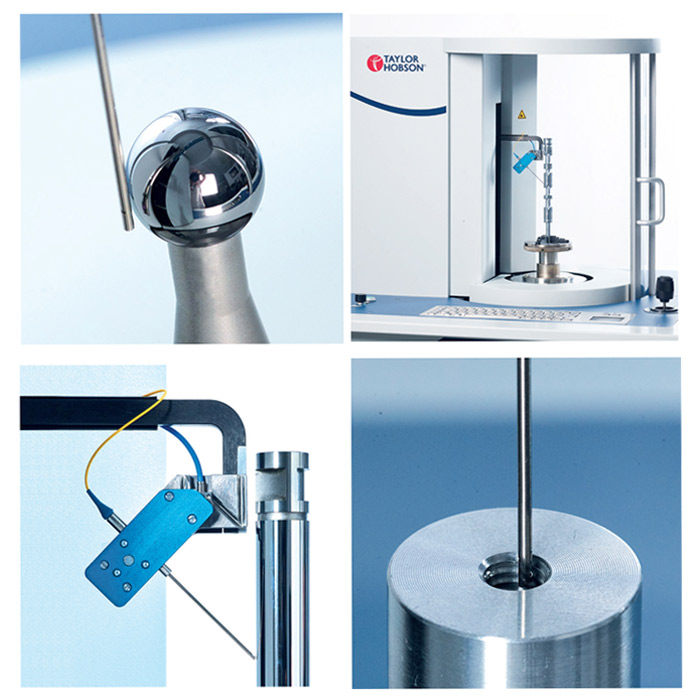

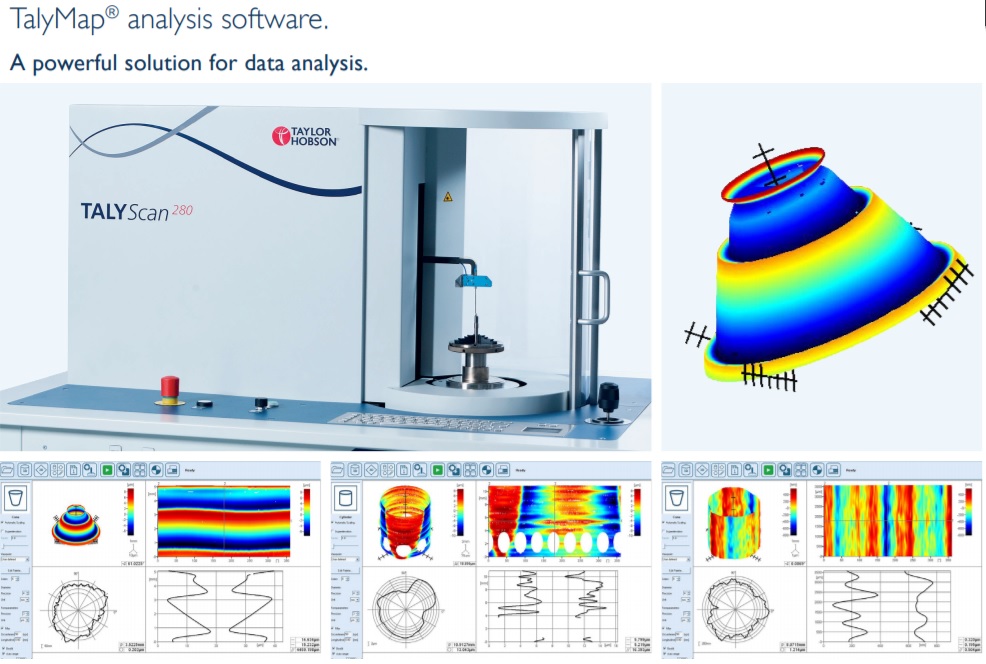

The TALYScan 280 is the ideal instrument for the inspection of roundness, straightness, parallelism, taper, roughness and diameter, all from a single full 3D scan.The system is designed to deliver high accuracy measurements of injectors, hydraulic components, lens barrels, roller bearings, precision bores, precision and thin walled cylinders.

The TALYScan 280 is easy to setup and program with powerful, intuitive and user-friendly software.

Surface finish and form measurement in one scan.

The non-contact probe utilises short coherence heterodyne interferometry, measuring changes in distance with a resolution down to the nanometer level. High speed measurement with speeds up to 200 rpm deliver high throughput of parts. TALYScan 280 software handles large amounts of data with 9 million data points in one scan. Powerful 3D analysis enables the operator to view surface features and defects in greater detail as never seen before.

LUPHOSpot probe safety features:

- Breakaway 3-point connection probe.

- Magnetic contact that protects sensitive probes from accidental damage.

- Capacitive sensor, detecting displacement of probe in case of collision.

LUPHOSpot probe specifications:

- 10,000 data points per second (10 kHz)

- Gauge range: ± 50 µm

- Working distance: 500 µm

- Resolution: 1 nm

- Spot size: 9 µm

- Angle of acceptance: ± 2°

- Rough surfaces: up to Rz max. 10 μm

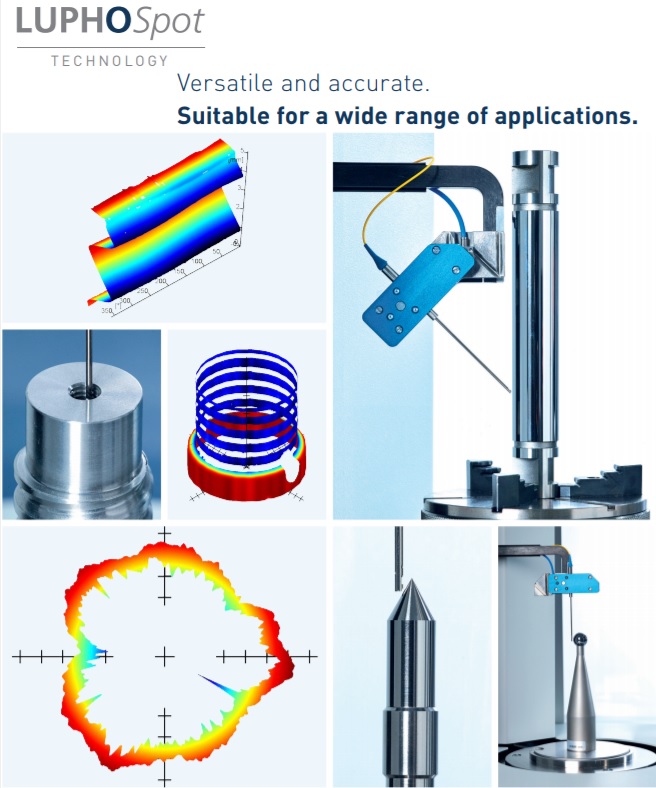

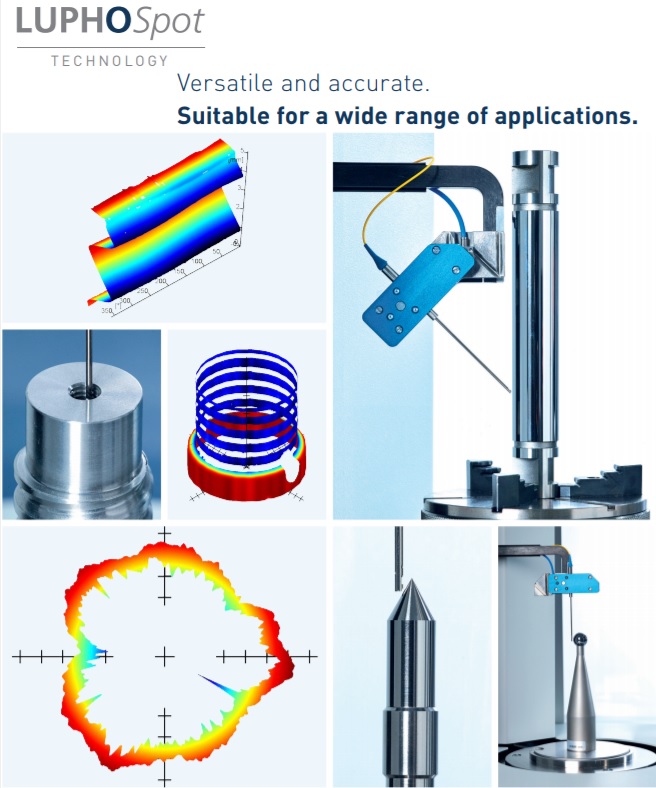

A new measurement technique to support modern design. Manufactured components are required to have high levels of quality, durability, precision and reliability in order to meet the demanding requirements of modern applications. The LUPHOSpot probe is capable of measuring a variety of materials and machined surfaces.

• Metal • Glass • Plastics • Ceramics • Ground, turned & polished surfaces

Applications:

Injectors

- Measure the complete part in 3D

- Access very small holes, critical for injectors (not possible with other instruments)

- Cones and cylinders can be measured in one setup

- A choice of small probes are available for internal measurements

- Interrupted surfaces can be scanned with clear, defined edges at high speeds

- Fast measurements over delicate surfaces

- Precision cylinders and bores

- A full 3D scan can be obtained

- The use of a 2 sensor probe to accurately obtain diameter

- No deformation of thin/long parts

Specification

High speed with no loss of surface detail.

Surface finish and form measurement in one scan.

The non-contact probe utilises short coherence heterodyne interferometry, measuring changes in distance with a resolution down to the nanometer level. High speed measurement with speeds up to 200 rpm deliver high throughput of parts. TALYScan 280 software handles large amounts of data with 9 million data points in one scan. Powerful 3D analysis enables the operator to view surface features and defects in greater detail as never seen before.

LUPHOSpot probe safety features:

LUPHOSpot probe specifications:

Surface finish and form measurement in one scan.

The non-contact probe utilises short coherence heterodyne interferometry, measuring changes in distance with a resolution down to the nanometer level. High speed measurement with speeds up to 200 rpm deliver high throughput of parts. TALYScan 280 software handles large amounts of data with 9 million data points in one scan. Powerful 3D analysis enables the operator to view surface features and defects in greater detail as never seen before.

LUPHOSpot probe safety features:

- Breakaway 3-point connection probe.

- Magnetic contact that protects sensitive probes from accidental damage.

- Capacitive sensor, detecting displacement of probe in case of collision.

LUPHOSpot probe specifications:

- 10,000 data points per second (10 kHz)

- Gauge range: ± 50 µm

- Working distance: 500 µm

- Resolution: 1 nm

- Spot size: 9 µm

- Angle of acceptance: ± 2°

- Rough surfaces: up to Rz max. 10 μm

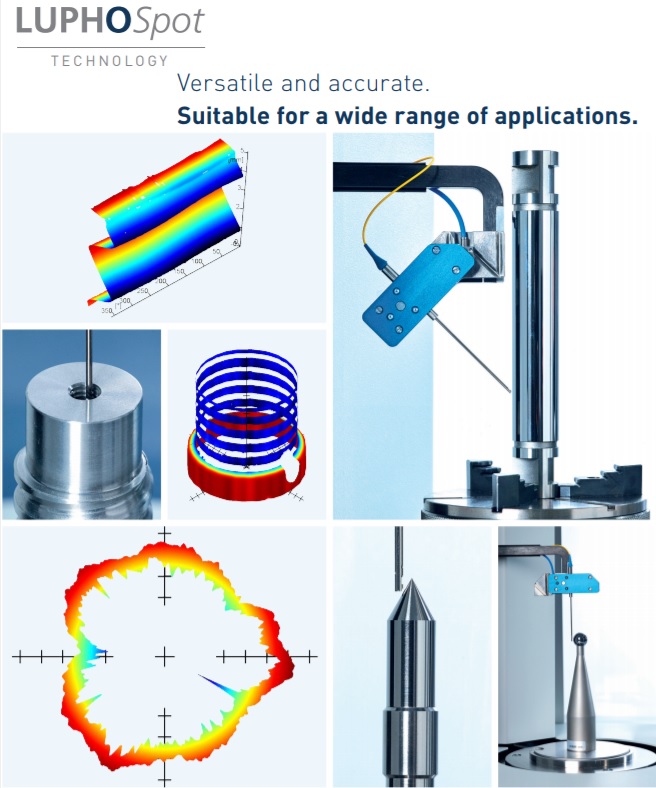

Applications

Supporting next-generation manufacturing

A new measurement technique to support modern design. Manufactured components are required to have high levels of quality, durability, precision and reliability in order to meet the demanding requirements of modern applications. The LUPHOSpot probe is capable of measuring a variety of materials and machined surfaces.

• Metal • Glass • Plastics • Ceramics • Ground, turned & polished surfaces

Applications:

Injectors

A new measurement technique to support modern design. Manufactured components are required to have high levels of quality, durability, precision and reliability in order to meet the demanding requirements of modern applications. The LUPHOSpot probe is capable of measuring a variety of materials and machined surfaces.

• Metal • Glass • Plastics • Ceramics • Ground, turned & polished surfaces

Applications:

Injectors

- Measure the complete part in 3D

- Access very small holes, critical for injectors (not possible with other instruments)

- Cones and cylinders can be measured in one setup

- A choice of small probes are available for internal measurements

- Interrupted surfaces can be scanned with clear, defined edges at high speeds

- Fast measurements over delicate surfaces

- Precision cylinders and bores

- A full 3D scan can be obtained

- The use of a 2 sensor probe to accurately obtain diameter

- No deformation of thin/long parts

Practice