Overview

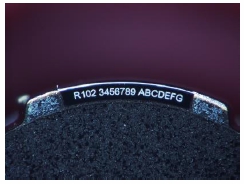

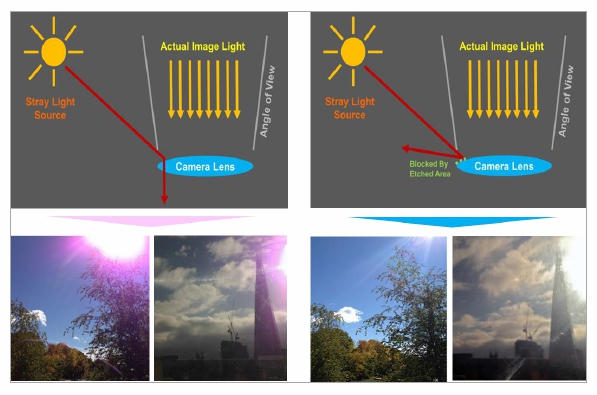

Camera Lens Flare Effect & SolutionIn order to prevent FLARE EFFECT such as blur images caused by stray light from out of angle of view, it is the solution to block the light transmission by etched roughness on the mold surface relevant to lens edge area which make stray light source scattered or refracted or reflected.

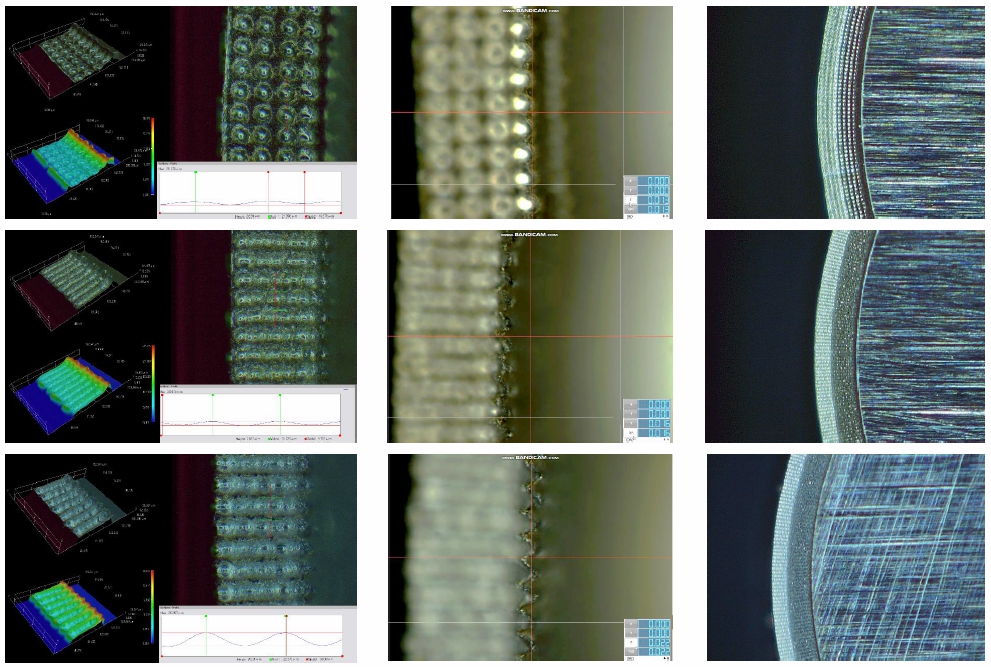

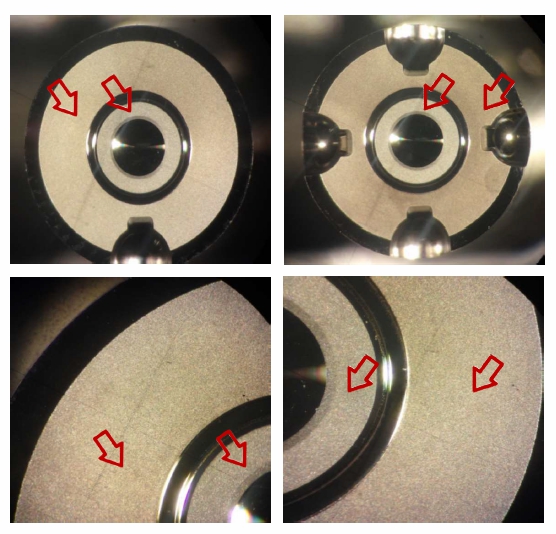

Laser Surface Treatment of Pin Core / Barrel Core

Traditional Electrical Discharging or sand blast process had been applied to surface roughness treatment (etching) on the core / barrel pin of lens injection mold but now, laser etching process gets the limelight by much better performance.

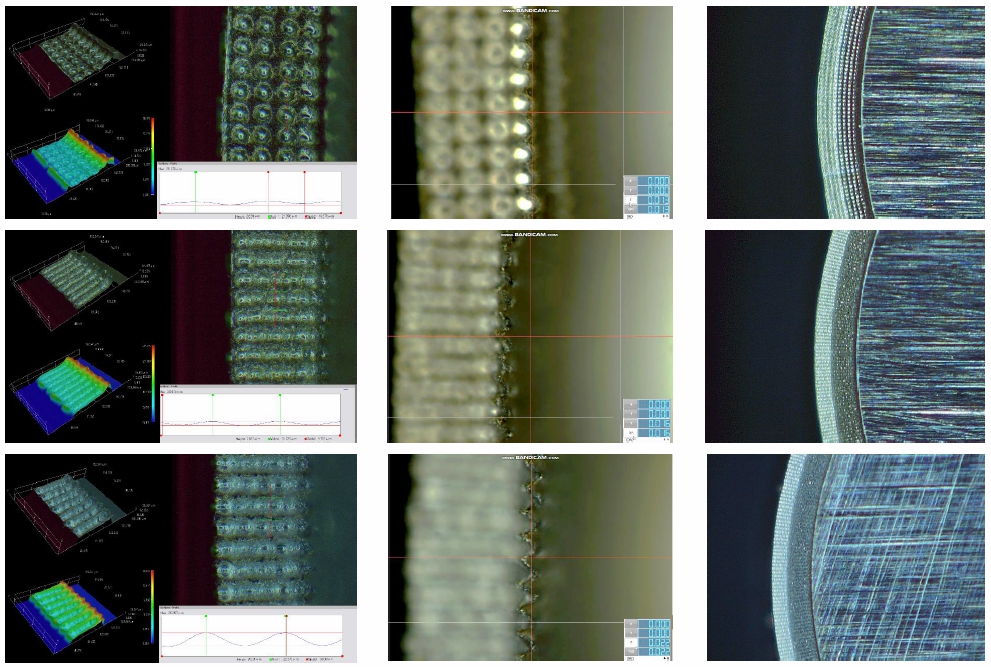

▶Laser etching (Hybrid Process of Ablation & Melting) makes the better quality than traditional methods.

▶UV pulse laser process puts more precise surface roughness and more uniformity in the control.

▶Nanosecond UV Pulse Laser: Minimizing the thermal effect.

▶High Precision:±5um (±3um achievable)

▶Movement:Mini. Pitch 1 um

▶Flexibility:Multiple axes(3-5 axis)

| Specification | |

| Capacity | 50mm X 50mm |

| Spot size | 12μm~25μm |

| Cut depth | <3μm (depending on laser power & process time) |

| Rotary stage | 0~30° |

Speicification

| Specification | |

| Capacity | 50mm X 50mm |

| Spot size | 12μm~25μm |

| Cut depth | <3μm (depending on laser power & process time) |

| Rotary stage | 0~30° |

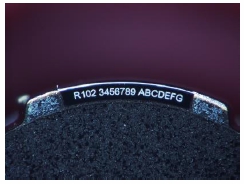

Practices