Introduction

Contour Fine Toolingwas founded in 1982 and has become the world's largest manufacturer of turning tools. The head office is located in the United Kingdom, but there are factories all over the world: the Netherlands, Brazil, China, Japan, the United States, Belgium and other countries. So it can quickly and flexibly support global new tool production, tool repair and complete after-sales service. At present, it has become the first choice diamond tools of many leading enterprises.

In addition, Contour gathers talents from all fields in ultra-precision machining to form a strong technical team lineup, which can provide customers with the most professional machining solutions and suggestions. We not only to sale, but to focus on the trust relationship with customers and long-term cooperation spirit.

Shank Material

• Steel

• Tungsten Carbide

• Molybdenum

• Titanium

In addition, Contour gathers talents from all fields in ultra-precision machining to form a strong technical team lineup, which can provide customers with the most professional machining solutions and suggestions. We not only to sale, but to focus on the trust relationship with customers and long-term cooperation spirit.

Advantages of Contour

High Quality

Inspection before shipment is the key to keep high quality. Contour has advanced exclusive manufacturing and measurement technology. These two technologies both ensure the perfect quality of contour products

According to the customer's application requirements, the waviness of finishing tool can be controlled between 0.05um ~ 1.0um, even better than 0.05um.

Flexibility & Customization

According to different waviness requirements, application requirements and interference considerations of customers, special tools can be customized.

In addition, we can also cooperate with the design of the tool holder mechanism of specific brands, such as: Son-X, TAGA, Sterling, etc..

High Durability

We carefully select non-dark brown, flawless diamonds without carbon spots to ensure tool life and reduce cracks and quick edge break down.

We have advanced production technology to effectively reduce the structural damage caused by external forces to diamonds.

Contour adheres to our manufacture principles and produces precise tools with long life.

Inspection before shipment is the key to keep high quality. Contour has advanced exclusive manufacturing and measurement technology. These two technologies both ensure the perfect quality of contour products

According to the customer's application requirements, the waviness of finishing tool can be controlled between 0.05um ~ 1.0um, even better than 0.05um.

Flexibility & Customization

According to different waviness requirements, application requirements and interference considerations of customers, special tools can be customized.

In addition, we can also cooperate with the design of the tool holder mechanism of specific brands, such as: Son-X, TAGA, Sterling, etc..

High Durability

We carefully select non-dark brown, flawless diamonds without carbon spots to ensure tool life and reduce cracks and quick edge break down.

We have advanced production technology to effectively reduce the structural damage caused by external forces to diamonds.

Contour adheres to our manufacture principles and produces precise tools with long life.

Tool Types

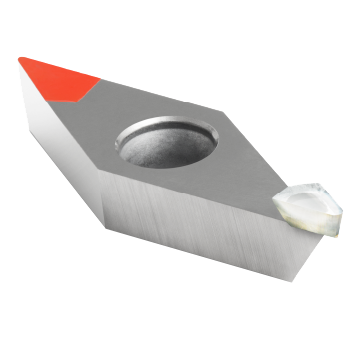

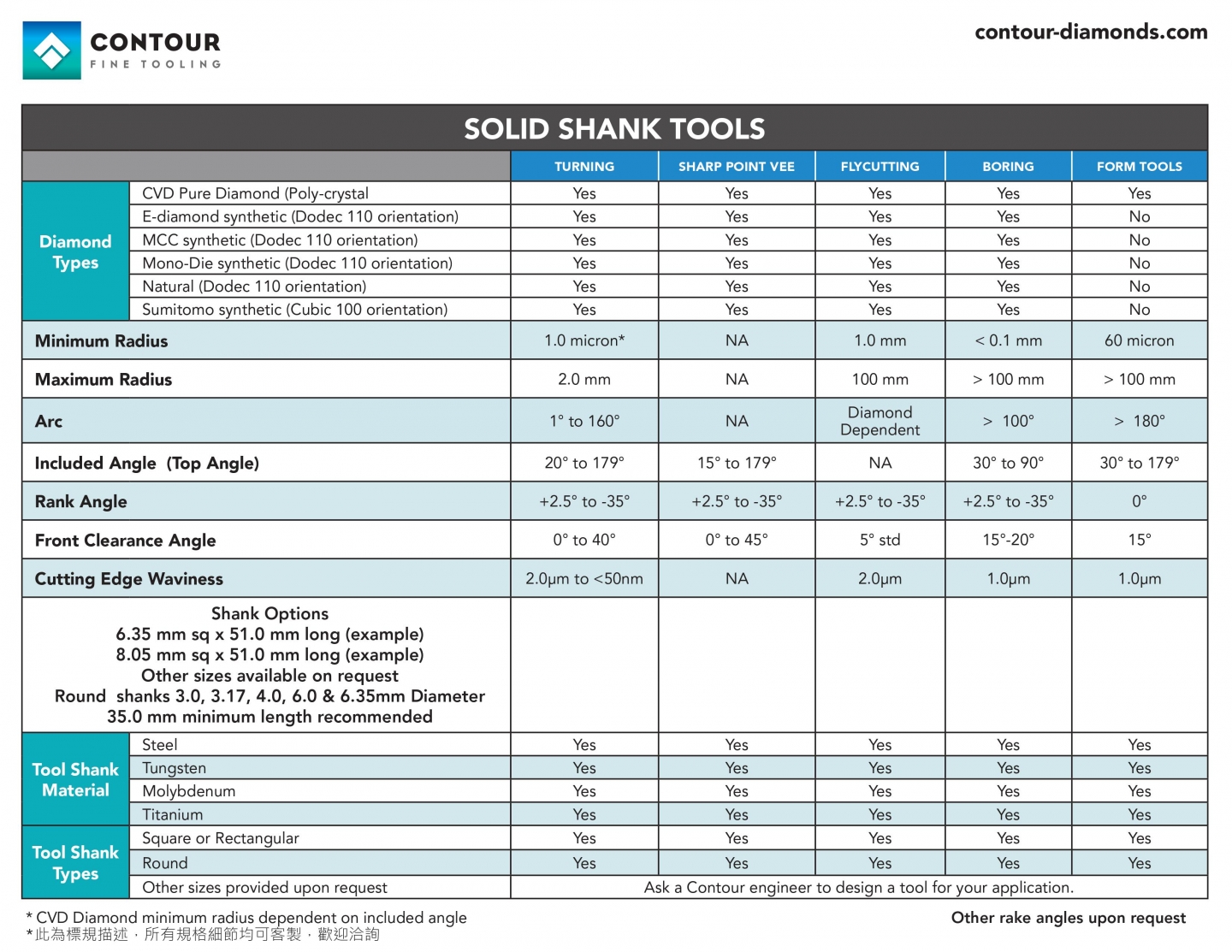

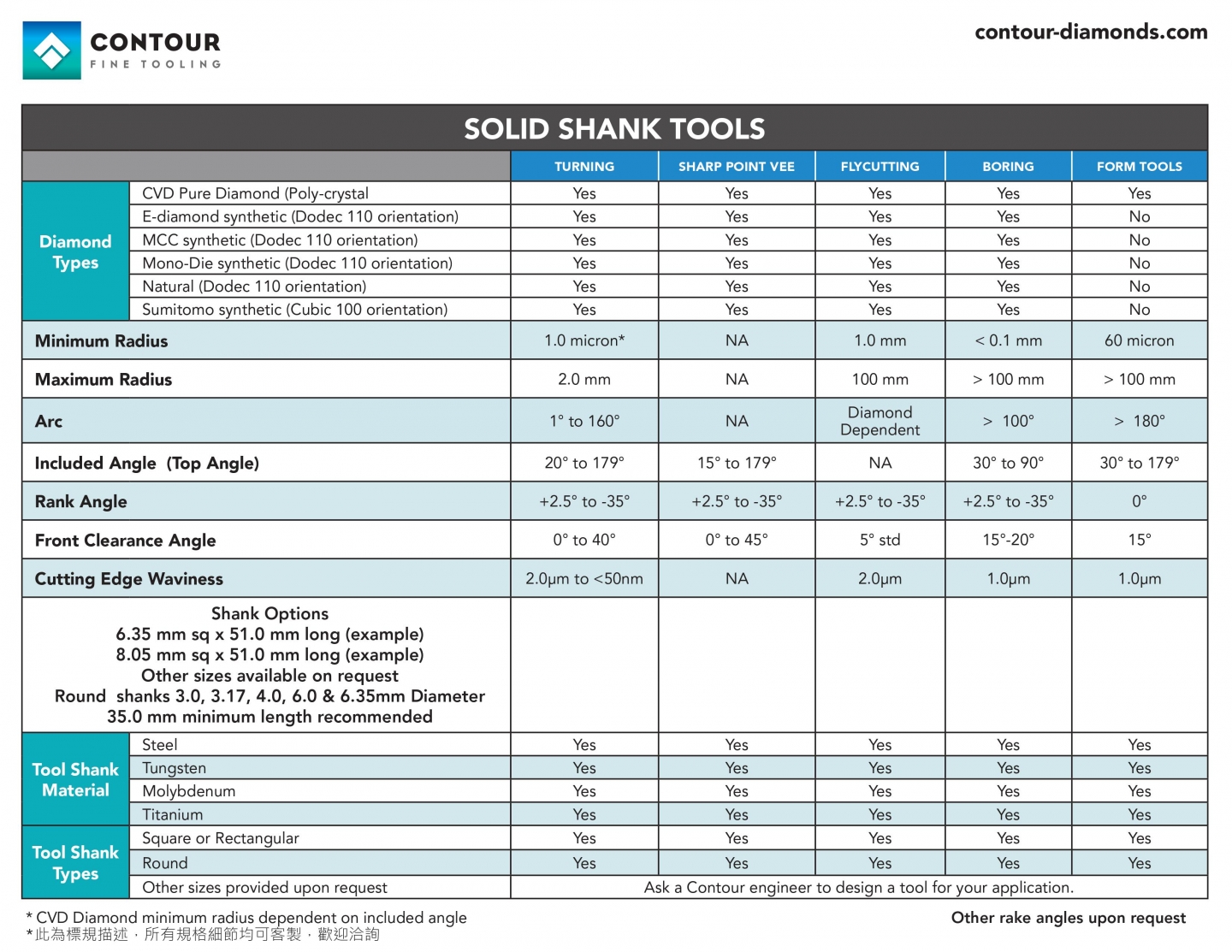

Solid Shank Tools

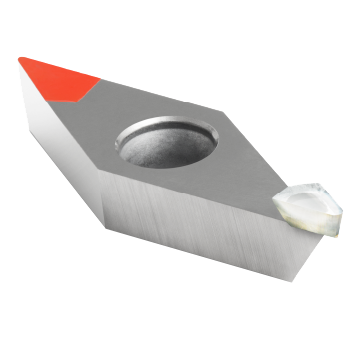

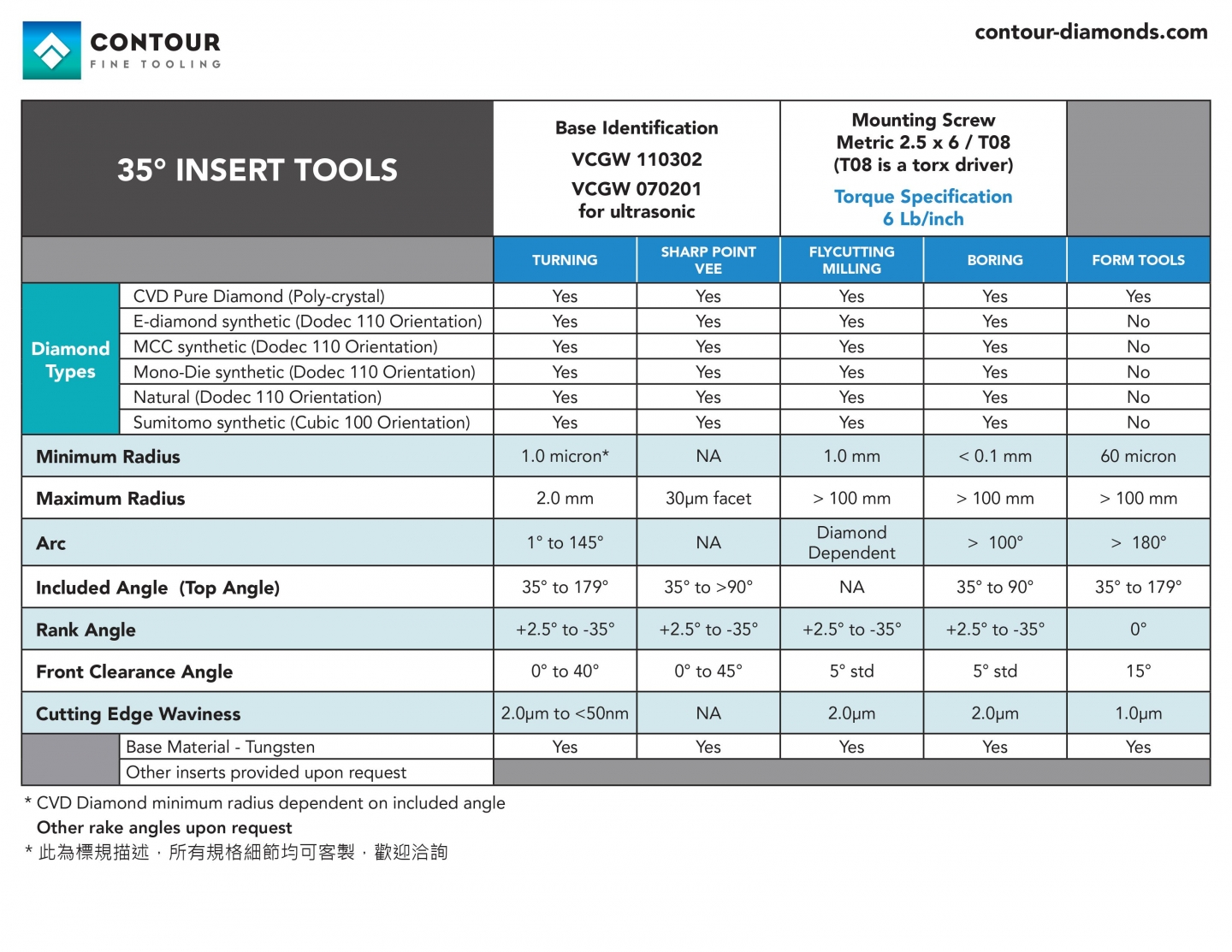

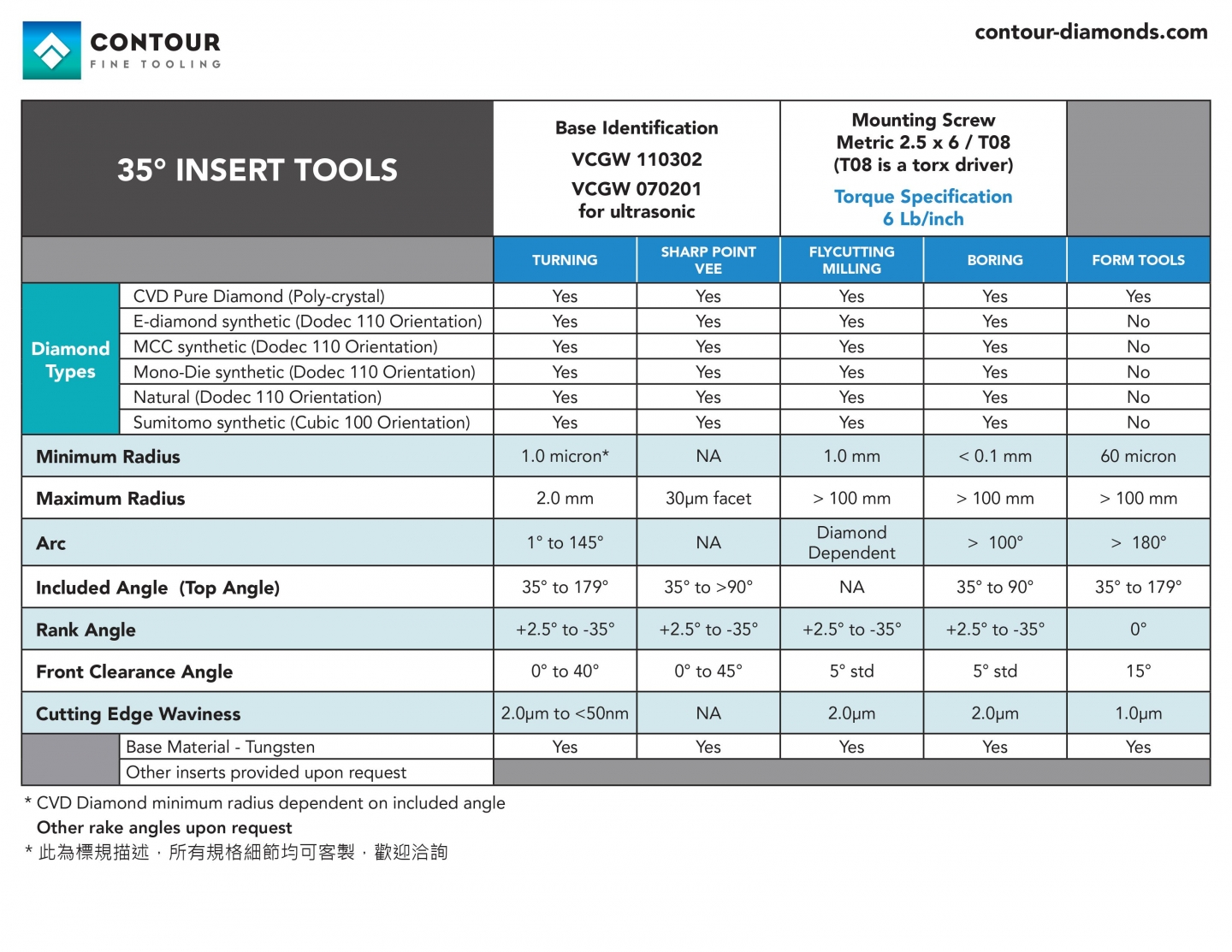

35° Insert Tools

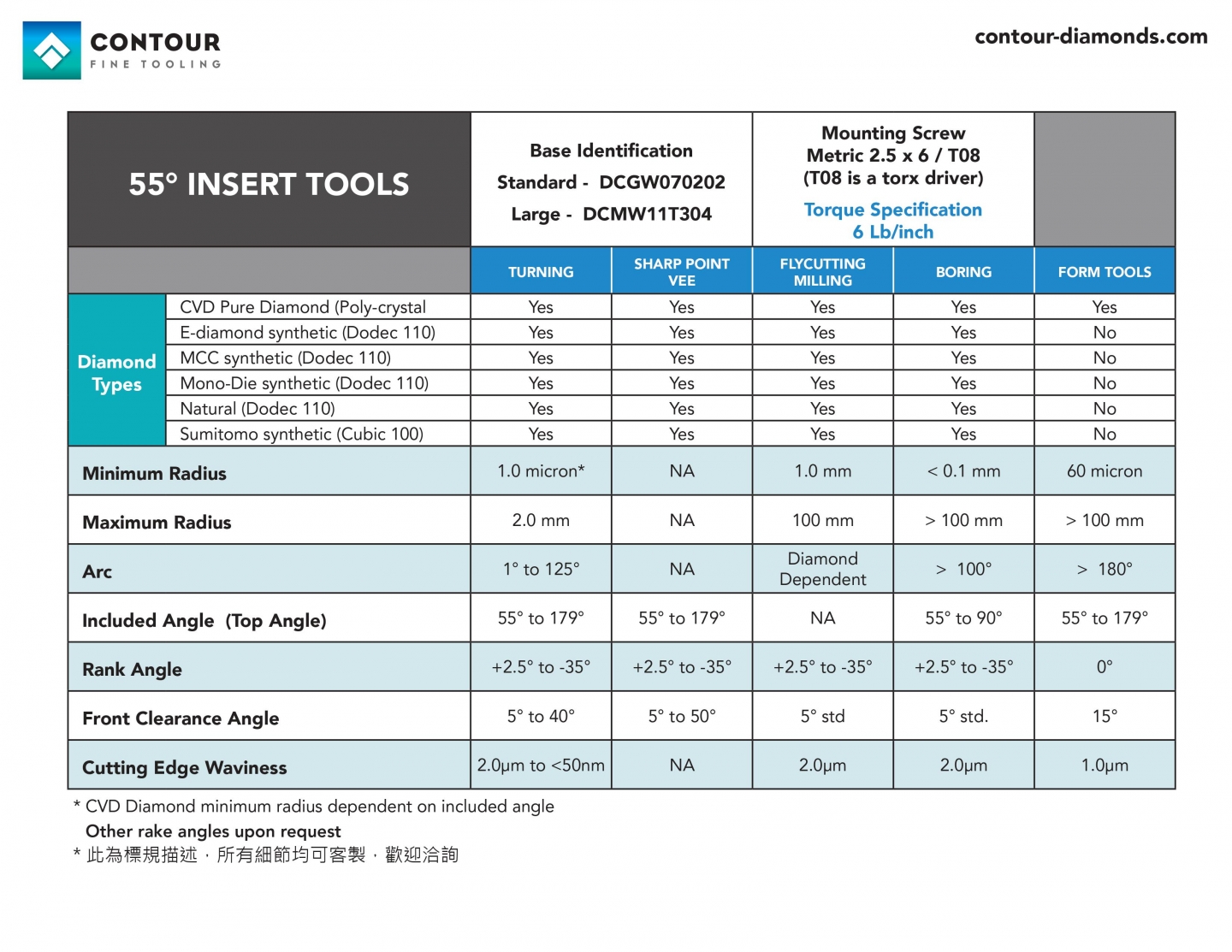

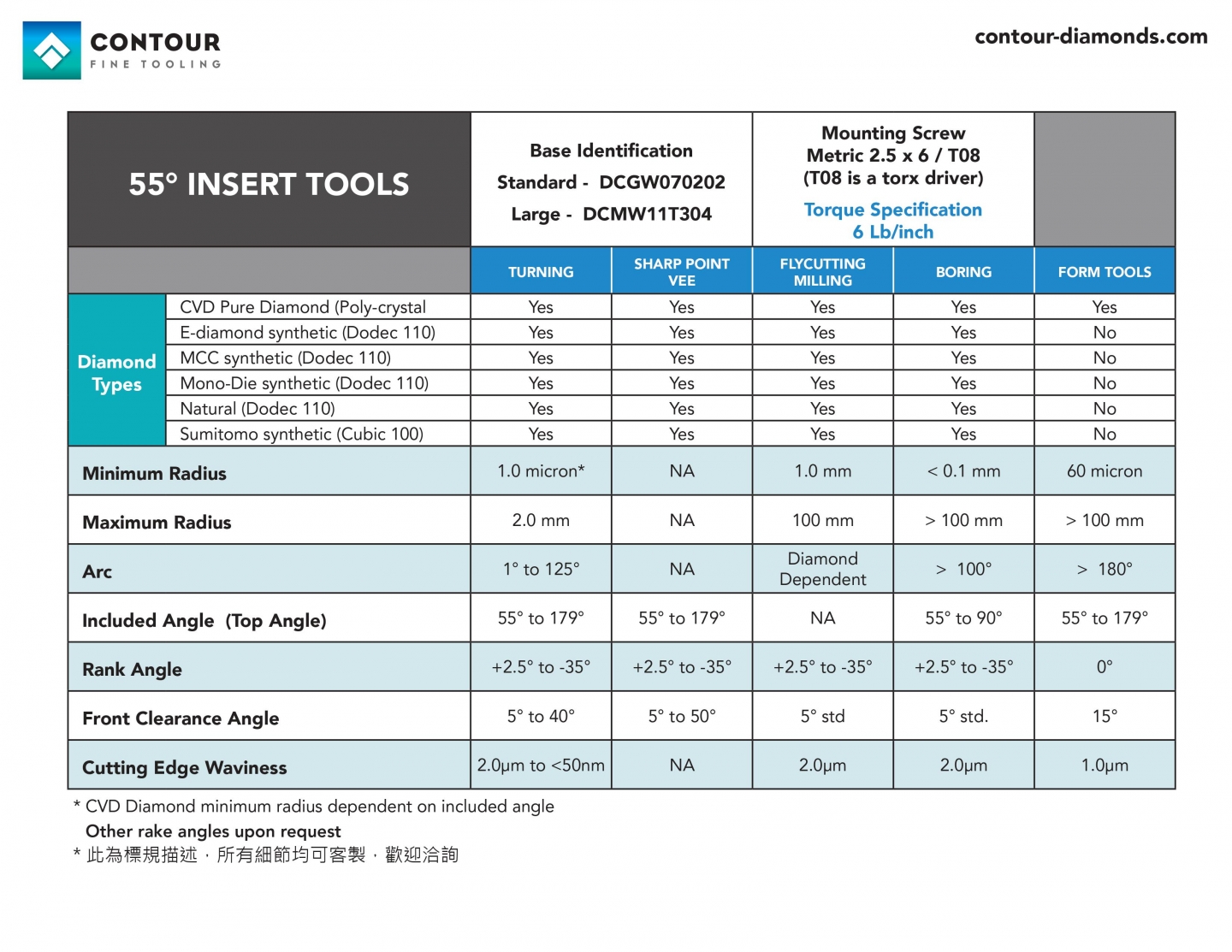

55° Insert Tools

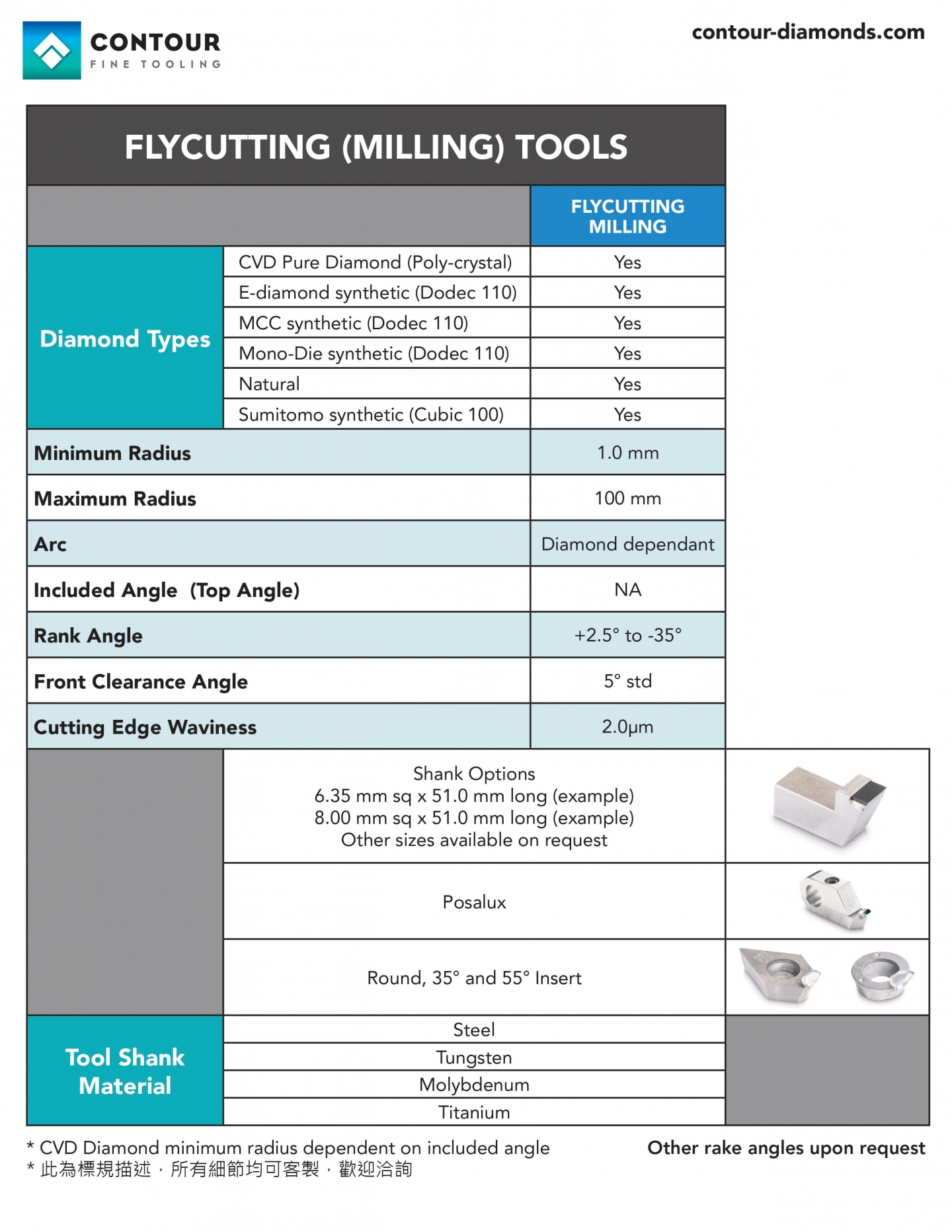

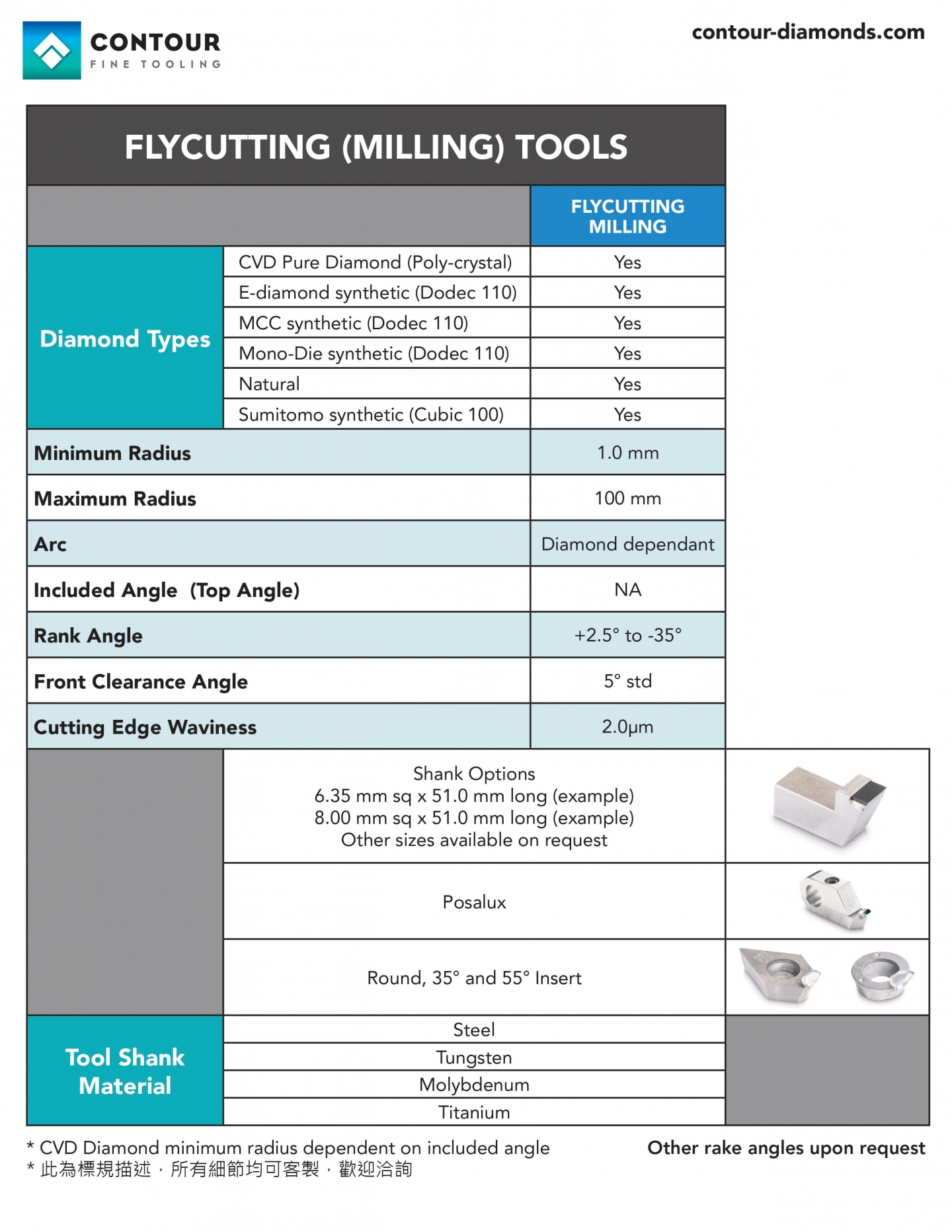

Fly Cutting Tools

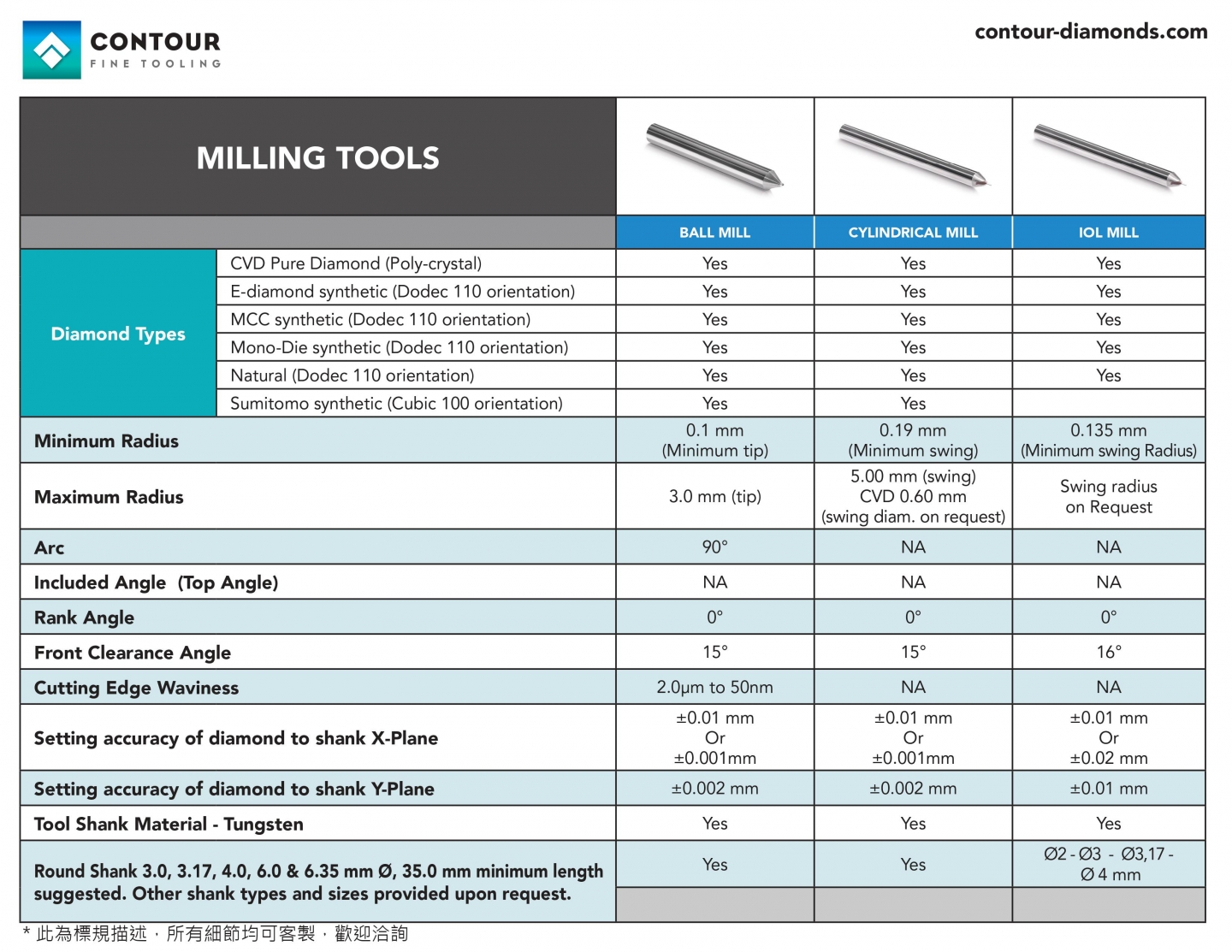

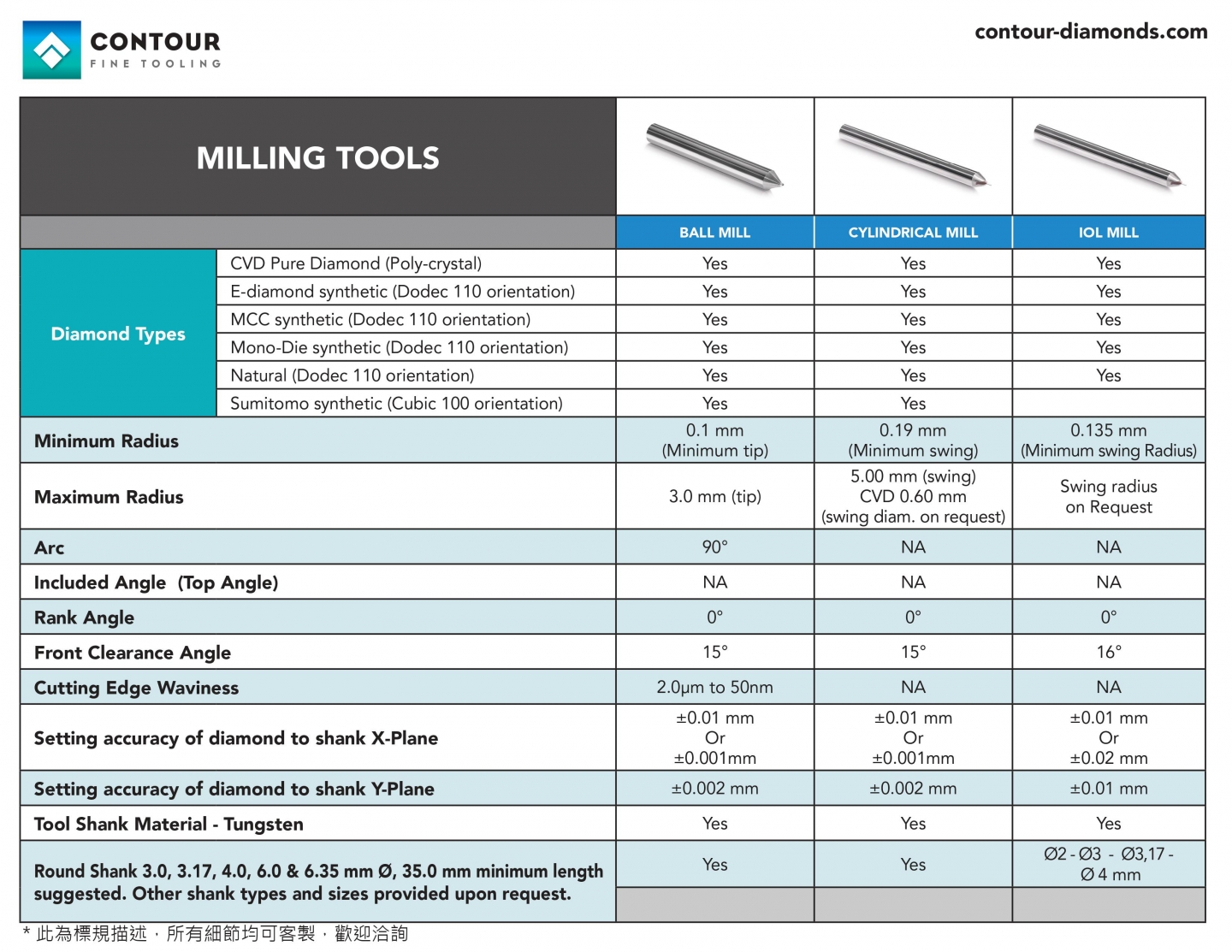

Milling Tools-Ball End Milling Tool、Half-Moon Cutter

35° Insert Tools

55° Insert Tools

Fly Cutting Tools

Milling Tools-Ball End Milling Tool、Half-Moon Cutter

Choosable Material

Diamond Types

• Natural (Dodec 110 Orientation)

• CVD Pure Diamond (Single-crystal)

• CVD Pure Diamond (Poly-crystal)

• E-diamond synthetic (Dodec 110 Orientation)

• MCC synthetic (Dodec 110 Orientation)

• Mono-Die synthetic (Dodec 110 Orientation)

• Sumitomo synthetic (Cubic 100 Orientation)

• Natural (Dodec 110 Orientation)

• CVD Pure Diamond (Single-crystal)

• CVD Pure Diamond (Poly-crystal)

• E-diamond synthetic (Dodec 110 Orientation)

• MCC synthetic (Dodec 110 Orientation)

• Mono-Die synthetic (Dodec 110 Orientation)

• Sumitomo synthetic (Cubic 100 Orientation)

Shank Material

• Tungsten Carbide

• Molybdenum

• Titanium

Machinable Materials

Non Ferrous Metals

Al, Cu, NiPh, Brass

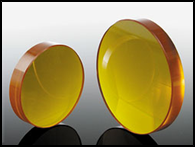

Crystals

Ge, Si, ZnSe, ZnS, LiNbO3, CaF2, BaF2

Al, Cu, NiPh, Brass

Crystals

Ge, Si, ZnSe, ZnS, LiNbO3, CaF2, BaF2

Polymers

PMMA, Zeonex

PMMA, Zeonex

Key Applications

|

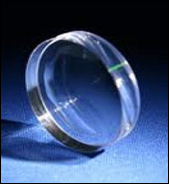

Spectacle Lenses

|

Contact Lenses

|

Intraocular Lenses

|

|

Structured Optics

|

Consumer Optics

|

Defense Optics

|

Solid Shank Tools

35° Insert Tools

55° Insert Tools

Fly Cutting Tools

Milling Tools